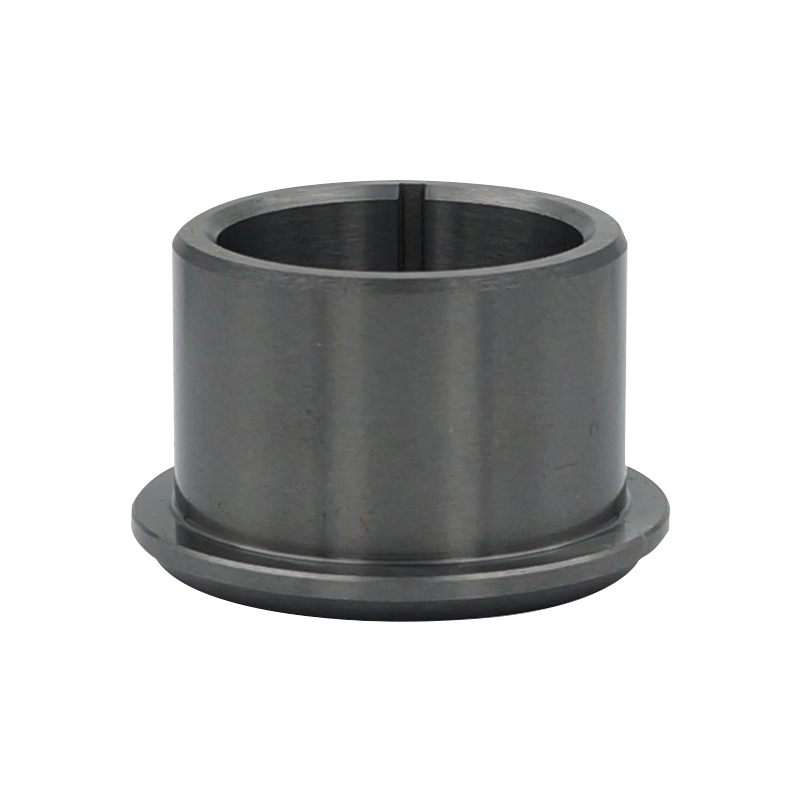

1. Enhance mechanical performance:

Cemented Carbide sleeves are made of tungsten carbide, a material known for its excellent hardness and strength. This enables the casing to withstand the high pressure and extreme temperatures experienced in oil and gas operations. The protective layer they provide can significantly improve the wear resistance of important equipment components such as pumps, valves, and compressors. By minimizing wear, the Cemented Carbide sleeve significantly extends the service life of these components and reduces the need for frequent replacement.

2. Corrosion resistance:

Contact with corrosive substances is common in oil and gas applications. Cemented Carbide sleeves have excellent corrosion resistance, which can protect equipment from the deterioration effects of irritating chemicals, acids, and salts. Therefore, they are widely used in key fields, including drilling tools, flow control devices, and downhole pumps, to ensure uninterrupted operation and reduce the risk of equipment failure.

3. Improve efficiency and reliability:

Cemented Carbide sleeves not only extend the service life of equipment, but also help improve the overall efficiency and reliability of the oil and gas industry. Through their excellent wear resistance, they can maintain the original geometric shape of the components and prevent irregularities that may hinder optimal performance. In addition, the reduction in maintenance and replacement requirements means an increase in normal operating time, thereby improving the productivity and profitability of companies in the industry.

4. Wide range of application areas:

Cemented Carbide sleeves have applications in various fields of the oil and gas industry, and have valuable advantages in each field. For example, in drilling operations, they are used for stabilizers, core barrels, and reamer shoes, improving the durability of these critical tools. In pumping systems, Cemented Carbide sleeves can protect the plunger, piston, and valve seat from wear and corrosion, ensuring reliable and efficient fluid flow. In addition, they are commonly used in well completion tools such as packers and underground safety valves, ensuring long-lasting performance even in the harshest environments.

5. Economic solutions:

By extending the service life of oil and gas equipment, Cemented Carbide sleeves provide industry operators with an economical and efficient solution. The reduction in maintenance and replacement costs not only saves valuable resources, but also minimizes downtime and related costs to the greatest extent possible. The company can allocate the budget to more critical areas such as exploration, production, and safety measures. Overall, cemented carbide sleeves have been proven to be a wise investment that can bring long-term benefits and enhance the profitability and competitiveness of oil and gas companies.

The use of Cemented Carbide sleeves in the oil and gas industry provides a reliable and effective method for extending the service life of critical equipment

Its excellent mechanical performance, corrosion resistance, versatility in applications, and cost-effectiveness make it an indispensable asset. By protecting components from wear, corrosion, and other damage factors, Cemented Carbide sleeves can ensure uninterrupted operation, reduce maintenance, and improve productivity. Adopting this solution enables the company to optimize performance while minimizing downtime and expenses, ultimately improving the overall profitability and sustainability of the oil and gas industry.